(SPONSORED CONTENT)

Did you know that one out of every five cars on the road today needs its serpentine belt replaced? Data from the Auto Care Association says that 20 percent of vehicles in operation need a new belt. And AAA reports that the No. 2 reason for towing is belt failure.

Five FEAD System Maintenance Tips

This underperformed maintenance routine offers great opportunity for you to recommend to your repair shop customers regular front end system inspections and maintenance. Here’s five recommendations from the Dayco tech team.

- Be proactive with inspections: Belts and their surrounding components should be inspected around 96,000 kms. They need to be changed around 125,000-130,000 km.

- Use a belt wear gauge: A general visual inspection is no longer enough. Recommend a tool like the aWEARness gauge from Dayco to identify rib depth and rib profile. Today’s belts are mostly made from Ethylene Propylene Diene Monomer, so they wear more like tire tread. This tool makes it much easier to tell the difference between a new belt and a worn belt so check out this video for a quick tutorial on how to use it.

- Look at the bearings: Visually inspecting the tensioner and pulley bearings is critical as worn bearings can lead to a number of problems.

- Listen up: A noise check is a necessity. Squeaks and squeals from the front end are a tell-tale sign that something is not functioning properly in the system. Often times it is NOT the belt – but it’s the result of tensioner misalignment or a worn bearing on the pulley.

- System replacement: Because components in a drive system wear at close to the same rate as the serpentine belt, replacing the tensioner and pulley helps avoid slip, noise or misalignment issues as well as reduces the risk of comebacks.

Are Your Shop Customers Getting Their Fair Share?

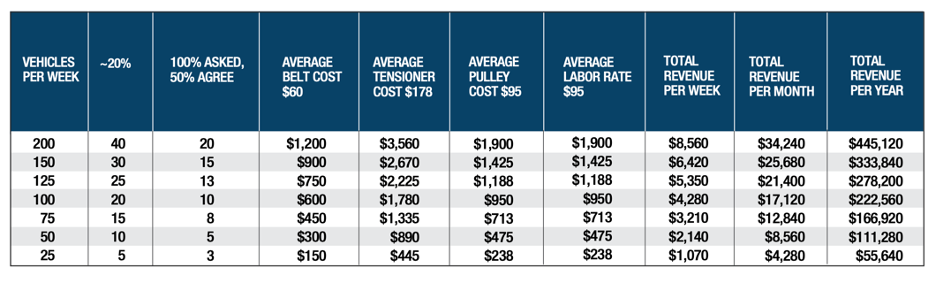

Replacing the whole system together isn’t only a best practice, it can also lead to more profitability and better customer satisfaction rates. So, make sure your customers are aware of this untapped market opportunity. If just 20% of the vehicles that need a belt replacement also have a new tensioner and pulley installed for best performance, the revenue increase will add up week over week.

Dayco Serpentine Belt Kits Offer One Complete Solution

Dayco light-duty serpentine belt kits have been designed for the most popular applications, offering coverage for almost 100 million cars, trucks and last mile delivery fleet vehicles on the road today. Each kit offers application-specific components needed to complete a front-end accessory drive (FEAD) system repair. They are also designed to handle higher workloads as well as enhance performance and service life when installed properly.

Providing shops with higher profit margins, less comebacks and better customer satisfaction, each kit includes:

- A patented tensioner with flat spring technology for longer product life

and overall quieter performance - Durable idler pulleys with permanently lubricated bearings, extending

belt life and reducing vibration - A premium, ultra-flexible serpentine belt or self-tensioning ela® belt depending on application

For more information on the full line of Dayco kits, click here.

Dayco’s Tech Hub Loaded with How-To and Training Content

Head over to Dayco’s Tech Hub for how-to articles and training videos – from our team of product specialists, certified techs and former shop owners. We’ve compiled content on topics like belt alignment, system replacement and more based on calls received through our tech hotline. And if you can’t find what you’re looking for, email us at partssupport@dayco.com.

0 Comments