(SPONSORED CONTENT)

Not all water pumps are created equal. In fact, some aftermarket pumps don’t meet OE quality standards so here’s a few tips to make sure you get the best performance and value for the cost:

- Verify the pump is thoroughly tested to ensure better performance.

- Make sure the pump meets OE fit, form and function.

- Ensure the water pump is made from high-quality components.

- Select a pump with a good warranty.

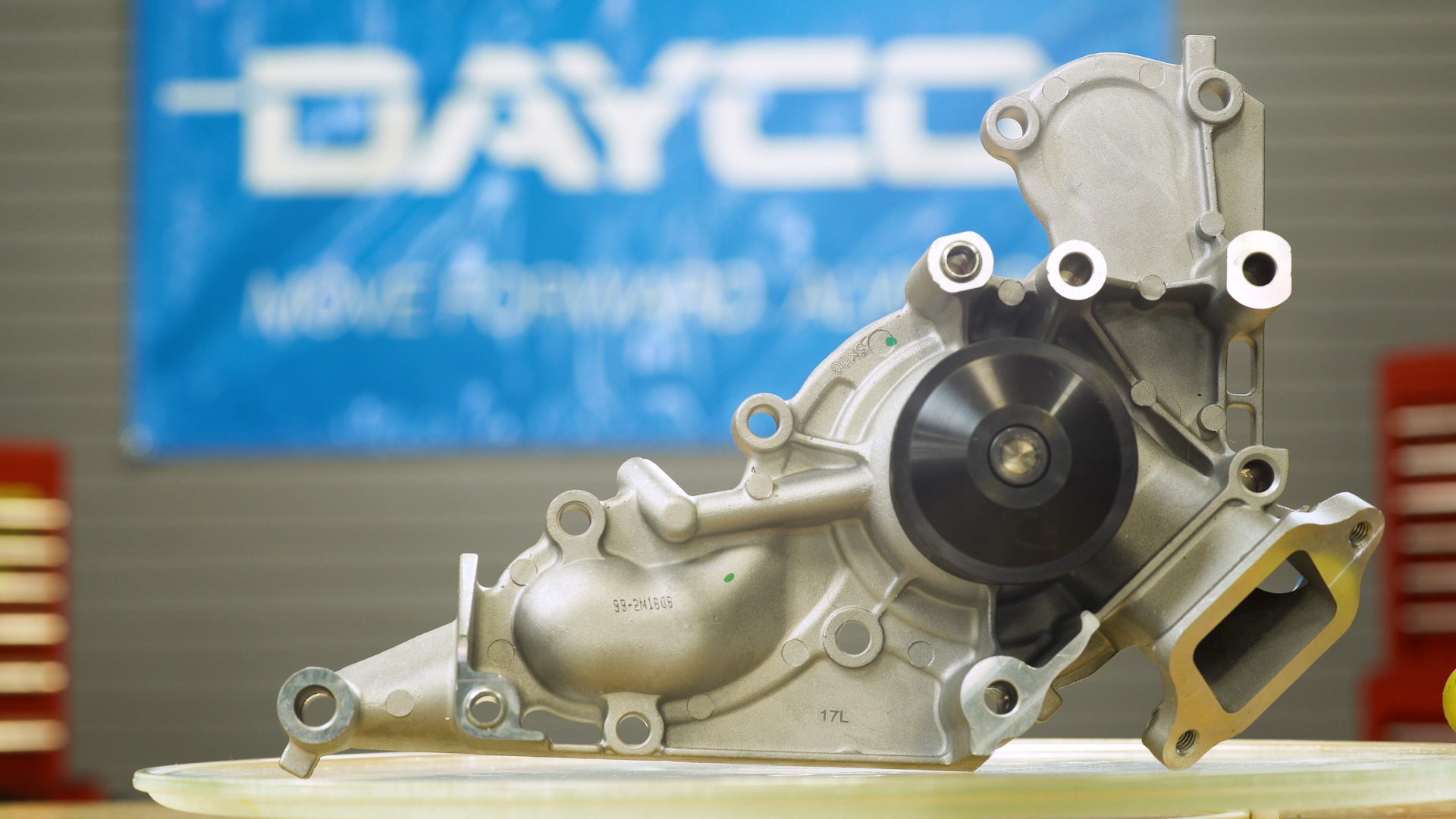

Dayco Pumps Designed to Go the Distance

Dayco offers a full line of water pumps for millions of today’s vehicles – all backed by a 200,000 km warranty to provide today’s repair shops with confidence in what they are installing. And unlike many of its competitors, Dayco has FULL control of the entire manufacturing process. Its pumps are end of the line leak tested and Dayco’s product team works directly with today’s car manufacturers on design to ensure their water pumps can handle extremely corrosive, high temperature environments. The Dayco offering includes:

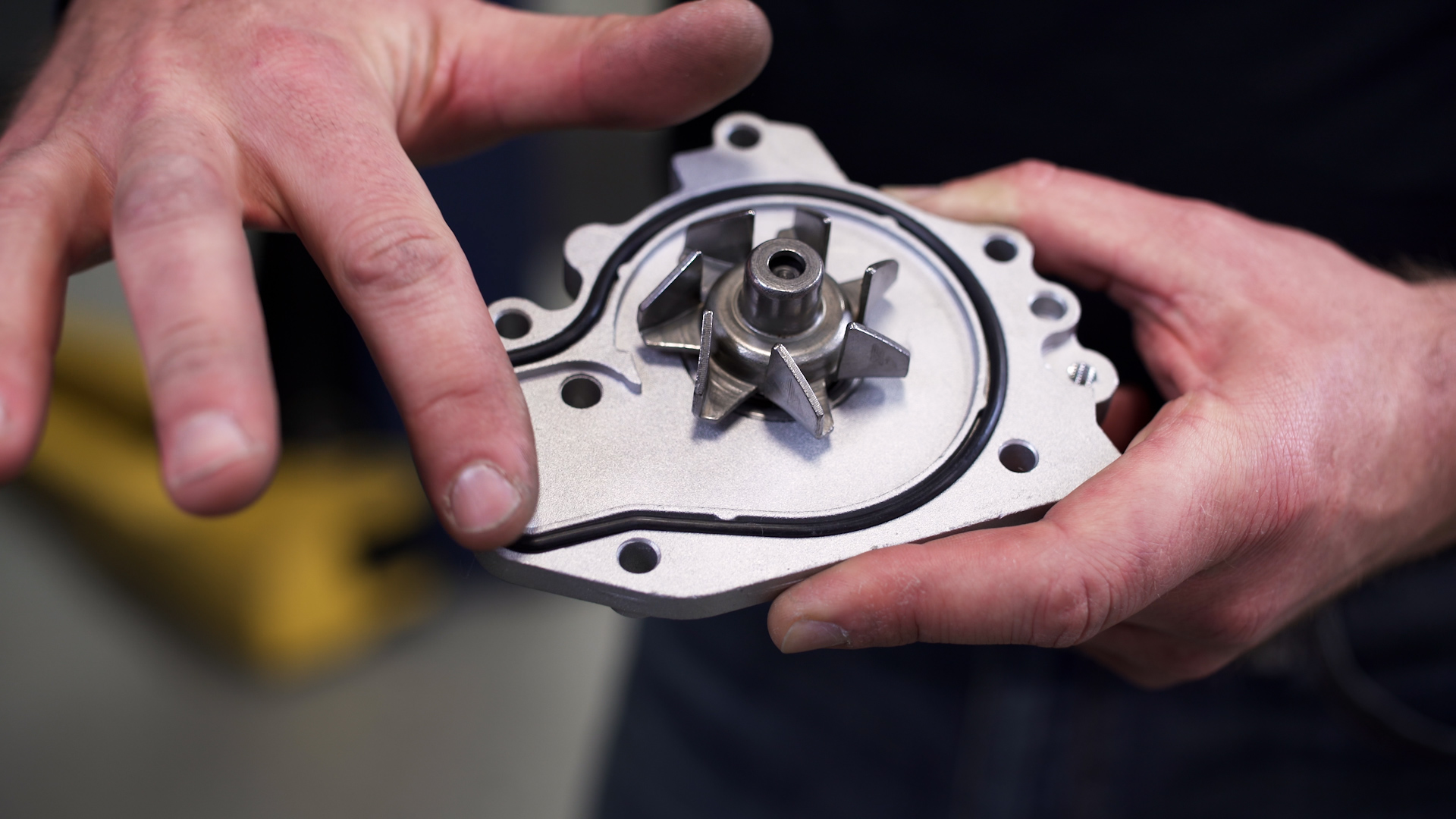

- Dayco mechanical water pumps that include gaskets made from high density materials to retain bolt torque and prevent wicking. They feature a case-hardened roller bearing in the hub, making them more robust than pumps that use standard ball bearings. Plus, silicone/carbide composite seals are used to prevent leaks well beyond the life of the expected warranty.

- Dayco electric water pumps that are OE-designed for millions of start/stop and hybrid applications. They are direct fit bolt-on replacements that do not require modifications during installation. Dayco’s electric water pumps include self-lubricating, graphite composite corrosion-resistant bearings, as well as tapered motor brushes for quick break-in. Select applications also come with an aluminum cover design that is more robust than many OEM plastic pump covers.

Ensuring Proper Installation

All Dayco water pumps are designed to last upwards of 200,000 km but sometimes pumps fail due to errors that occur during installation. The tech team at Dayco has pulled together the top three mistakes they hear about during water pump replacement that could impact the life of the product:

#1 – Coolant Confusion

A 50/50 ratio of coolant and water is needed for proper performance. Diluting or enriching coolant mixture removes anti-corrosive properties and impedes additives designed to keep fluid from freezing or boiling. This small mistake has BIG consequences since it can damage the pump seal and cause failure way before the product’s intended service life.

#2 – Failure to Flush

Technicians should replace the coolant when a water pump is changed – 95% of water pump failures occur due to this mistake. If a customer refuses the coolant change, they need to understand that the old coolant will not be able to keep the engine and other vital components at safe temperatures and can lead to early water pump failure. It is imperative to start with a clean cooling system with the correct coolant for long pump life.

#3 – Avoiding FEAD Component Replacement

Dayco highly recommends changing all worn front-end drive system components when a water pump installation is necessary. A systems approach is critical to component longevity so the system can work in harmony. A technician should also replace the water pump when performing a timing belt change because the pump is inexpensive and 90% of the labor needed can take place at the same time as belt replacement.

For more installation recommendations on both electric and mechanical water pumps, check out these Dayco tech videos:

3 Reasons Electric Water Pumps Fail

Mechanical Water Pump Installation Tips

0 Comments