Spectra Premium inaugurated a new charge air cooler (CAC) production line in Laval, Que., featuring new grommet-style technology. The use of grommets replaces the brazed tube to header joints which results in a more durable heavy duty part for truck applications.

“Thanks to the efforts of our product development team, Spectra Premium now proposes a longer-lasting charge air cooler solution for fleet management that reduces truck downtime. Proudly manufactured in North America, this new production line will strengthen our position in the heavy duty aftermarket for cooling systems,” stated Jason Best, Senior Vice-President Aftermarket of Spectra Premium.

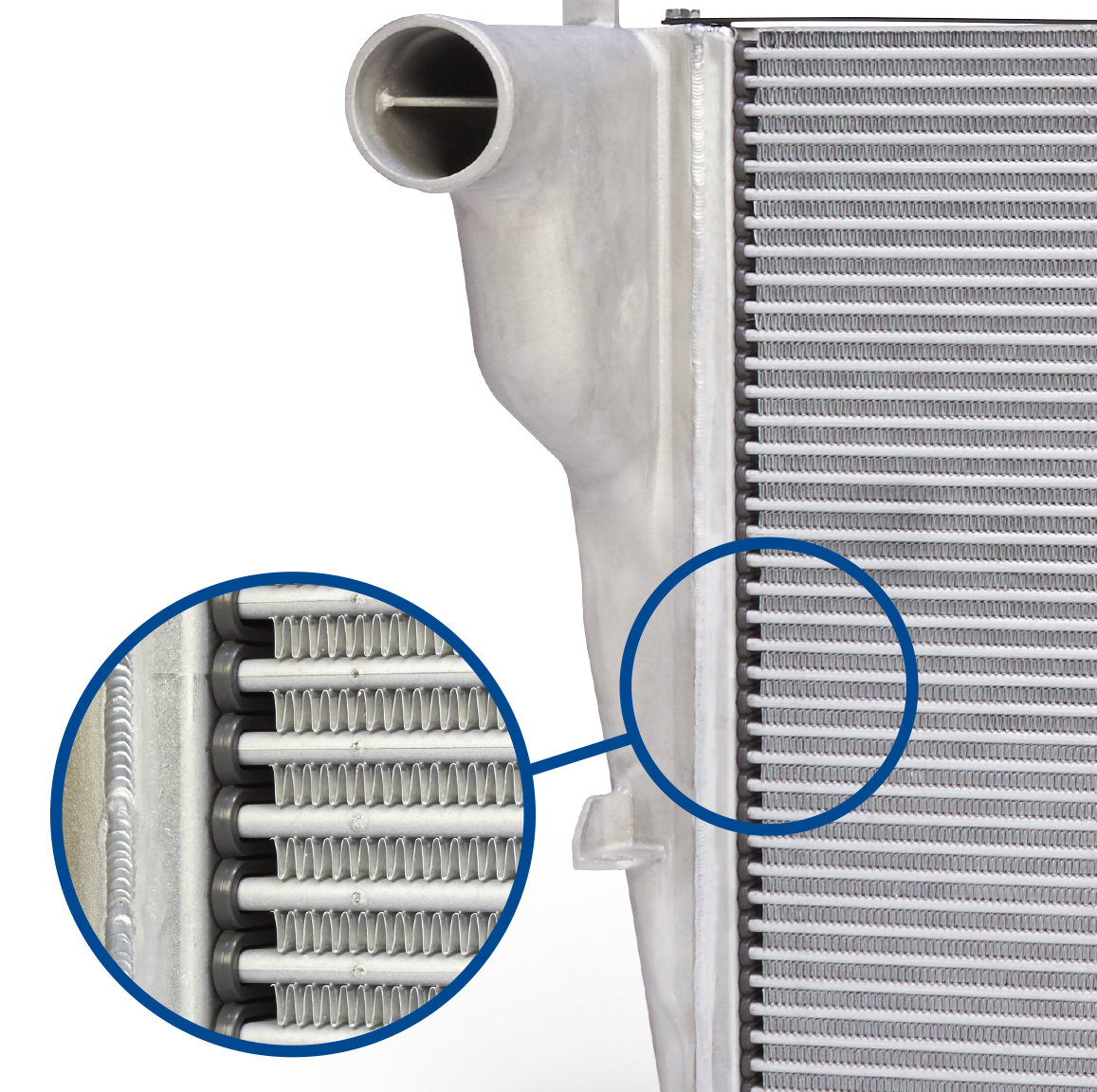

Charge air coolers (CAC) are subjected to thermal stress which, in time, leads to tube to header cracks causing leaks. The new Spectra Premium grommet construction style adds high-quality silicon joints to allow more movement and flexibility to the CAC core. Giving the tubes the room to freely expand and contract reduces stress on the core, resulting in a more durable heavy-duty part.

In addition to this improvement, Spectra Premium Charge Air Coolers have thicker reservoirs and use internal rods to maximize strength and consolidate the hold on the headers in order to better withstand pressure. Inside the reservoirs, baffles direct the air flow evenly within the charge air cooler, balancing the strain across the tubes.

These charge air coolers are engineered and manufactured at the Spectra Premium facility in Laval, Quebec using only the highest grade aluminum alloys and high-performance silicon.

0 Comments